Plastic Projects

Our Project team has acquired a vast amount of experience working with multiple machines in the plastic industry.

Injection molding

REMU 1800 Ton Injection Mold Machine Control System Upgrade

A Cape Town company recently had one of its original machines malfunction due to the control system shorting. This Injection molding machine is their only producer for the larger product range. We were commissioned with the task of reviving this ancient 25-year-old Italian machine. Applying our previous strategy of cost efficiency we proceeded to analyze the existing equipment we would be connecting to.

The challenge we faced with this machine was the tie bar clamping compared to previous toggle clamping machines.

This endeavor was proceeded by ourself and after running through all necessary equipment and requirements to be met, we proceeded with the development of control panels.

Our Project execution plan was:

- Identifying the important cables with the Electrical diagrams

- Remove all unnecessary and legacy systems not required for our new system, e.g. power supply, old relays, defective control unit.

- Install and Mount all relevant units for our new System, e.g. Main Control Panel, SmartMold HMI Panel, and various relays/solid-state relays

- Identifying Valves and corresponding cabling for proportional valves and coil valves.

- After confirming all termination and wiring to be correct. We proceeded with doing Hydraulic and I/O testing.

- Lastly, we completed the Euro-map 12 interface between the robot and the control system, which allowed the customer to run the machine in full autonomous mode

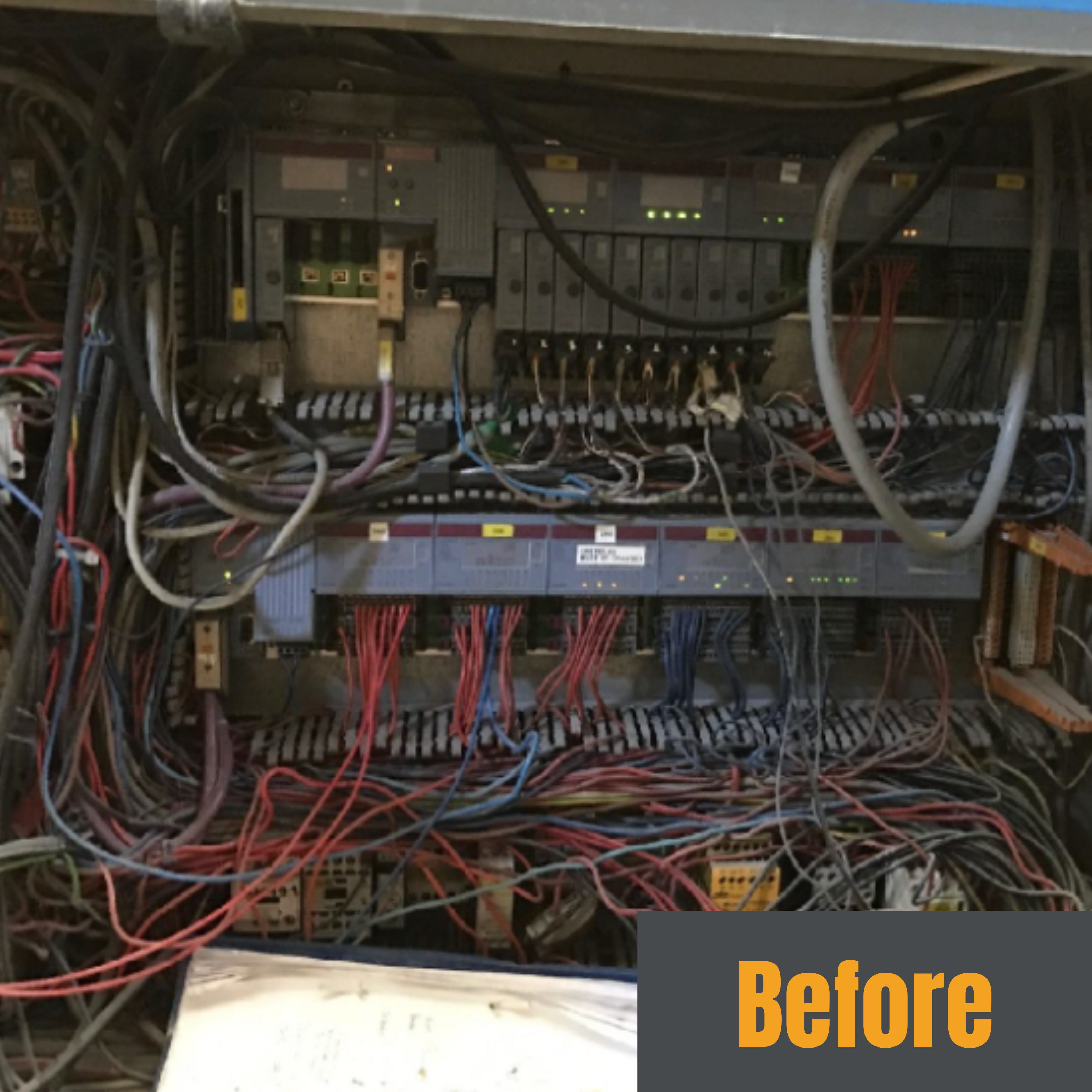

Original Panel

All-New Units Installed

Analysis conducted on the machine provided insight on the procedures and extras required to complete this project.

The hardware we selected was our Upgraded version of the SmartMold Injection Molding Machine Controller developed by B&R Austria. After Building the Main Panel, Barrell Heating Panel, and Blank-out Panel, we gathered our equipment and headed on a long haul down to Cape Town.

UBE 450 Ton Injection Mold Machine Control System Upgrade

We were challenged with upgrading a 30-year-old Injection Molding Machine for a European-based OEM. The Machines are past the point of their standard upgradability, hence we were given the task of developing and designing a solution that could get the machine functioning and producing products in a cost-effective manner.

We accepted the challenge and made our way to the customer based in the United Kingdom, to identify all the necessary equipment needed in order to proceed with this retrofit upgrade.

Thereafter in conjunction with the machine manufacturer and the customer, we concluded on the necessary equipment and control system to carry out the development for the project.

Our Project execution plan was:

- Identifying and marking all pre-existing cables and signals to the machine.

- Remove all unnecessary and legacy systems not required for our new system, e.g. power supply, old relays, defective control unit.

- Install and Mount all relevant units for our new System, e.g. Main Control Panel, Hot runner Panel, SmartMold HMI Panel, and various relays/solid-state relays

- After confirming all termination and wiring to be correct. We proceeded with doing Hydraulic and I/O testing.

- Thereafter, we commenced with our initial commissioning and carried out this process until the machine was then able to automatically produce quality parts.

- Lastly, we completed the Euro-map interface between the robot and the control system, which allowed the customer to run the machine in full autonomous mode

Original Panel

After our findings from our preliminary visit, we set about designing the control system and electrical drawings in order to manufacture the control system panel.

The hardware we selected was our tried and trusted SmartMold Injection Molding Machine Controller developed by B&R Austria. After building the Main Control Panel and Hot Runner panel for mold heating, we proceeded to ship a crate possessing all the equipment required to complete the project.

All-New Units Installed

Special Thanks to our project leader

Austin Moodley – hold the first quality produced product

It has now been 6 Months after the completion of the project. We have only received positive feedback from the customer. They require us to asses a couple of other Injection molding machines for upgrades. The 2024 has been our most productive year for Injection Molding Machines with two completed thus far.

Injection molding

REMU 1800 Ton Injection Mold Machine Control System Upgrade

Automation Republic offers many upgrade options to bring an old machine back to life and improve performance.

To the right is an example of an Extruder Control System Upgrade on an old outdated machine. Automationn Republic refurbished the panel and completely redid the wiring as well as adding a new PLC system and fresh new software to make the old machine run like new. The project involved taking just about everything and putting in a completely new PLC system and redid the wiring.

Injection molding

Blow molding machine upgrade

Using B&R Seamless Integration of complex extras

Automation Republic executed an extensive upgrade on a blow moulding machine. The project involved seamlessly integrating takeout robots, in-mould labelling robots, hydraulic scrap remover and needle blow onto the B&R blow moulding control platform which is now running on a Power Panel 400 embedded HMI/PLC with X20 IO.

An 8-layer parallel control sequence allows for adjustable movement ensuring that the machine can handle even the most complex of tasks. Each movement in the process chain has a delayed adjustable with a resolution of 10ms. The hydraulic mould movements on the machine involve proportional control of flow valves based on analog feedback from position transducers. The hydraulic blowpin movements, however, are simple proxy to proxy movements with directional hydraulic valves and robot movements that are all pneumatically controlled.

Dual Carriage Extrusion Blow Moulder Upgrade

Fastest possible turnaround with B&R control system

Automation Republic recently completed a control system upgrade on an old dual carriage extrusion blow molding machine. The upgrade took only 5 days from arrival on site to full production! This super-fast turn around time was made possible by the pre-written B&R blow moulding software

It is commonplace in many factories to find machines that have been shelved due to ageing control systems. In many cases, these machines are mechanically still in near perfect condition and they end up being put aside only because of the cost of replacing failing electronic control components that are becoming obsolete. Automation Republic provides an opportunity to breathe new life into these machines.

A perfect solution in the case of extrusion blow moulding machines is the B&R blow moulding upgrade solution. A fully developed touch screen HMI with process animation provides an intuitive operator interface. Software from B&R which is already 80% complete means a less ‘buggy’ experience than many other upgrade solutions on the market which often require software to be written from scratch. The turnaround time for the installation is also unusually fast among the competitors in this segment.

Injection Moulding Machine Upgrades

B&R SmartMould

Complicated electrical control systems, although ruggedized to varying extents, are usually based on similar technology to PC’s and expecting them to perform day after day in the often harsh production environment for years on end is of course, unrealistic.

It is normal for the downtime on machines with electronic control systems to increase exponentially as a function of time due to the decreasing availability of components, greater difficulty in troubleshooting as problems become more stochastic, complex and interlinked and the increased chance of failure of these components due to years of daily wear and tear. These challenges are compounded by the fact that older components generally become more expensive as the volumes of their global use decrease. Constantly repairing these systems is akin to trying to repair a 10 year old computer at an ever increasing price with ever worse reliability and functionality as the end result. As with the computer it makes much more sense to simply replace the control system with a new one.

Succesful local installations include machines for AstraPak, Venture and Boxmore.

Upgrading a machine’s control system comes with its very own set of problems however. Many factories have had a failed upgrade attempt or two which has probably led to the machine being scrapped or cannibalised for spare parts or often having ‘buggy’, niche software leaving the machine owner forever tied to the company or person that did the upgrade for support. This kind of solution also can leave machines with decreased functionality and worse production quality than the original.

The solution is simple, upgrade using a system which is in serial production with thousands of successful implementations world wide. A system which is supported by one of the top automation companies in Europe. A system which guarantees availability of spares and support for 10 years and have it installed by a company with a track record of success with installation of the system in your market.

Injection Moulder Machine Control System Upgrade

This project included a control system upgrade which was executed by removing the existing CPU and replacing it with the B&R smart mould. Existing hardware that was not obsolete was repurposed within the upgrading process. The machine was reprogrammed and commissioned on site. Installation of new hardware was conducted by the Automation Republic team.

Procedure:

1. Commence with programming at the Automation Republic office

2. Removal of existing, obsolete, hardware

3. Installation of new smart mould and control hardware

4. Program fine-tuning and testing

5. Commissioning

6. Handover

Smart Mould Upgrade for custom injection moulding machine.