Construction Projects

Our project team has acquired a vast amount of experience working with multiple machines in the construction industry.

Our project team has acquired a vast amount of experience working with multiple machines in the construction industry.

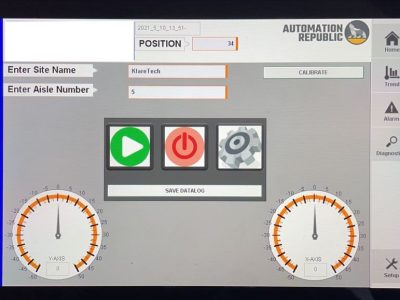

Automation Republic recently developed an instrument, called the Profilograph.

This device is responsible for accurately measuring deviance in floor heights over a defined width and length, usually the wheelbase of a forklift for example.

To achieve a high level of precision, the profilograph makes use of some extraordinary sensory equipment combined with B&R’s mobile CPU range, namely the X90 series.

The device is self-steering thanks to a vertically mounted camera tracking system, designed to follow a path laid out, ensuring accuracy, control, and repeatability.

We also developed a self tracking system using advanced camera software written in house. This system coupled with a servo steering mechanism allowed the unit to auto steer itself preventing operator intervention and resulting in a more accurate measuring system.

The system was designed to replace the conventional dipstick measurements, reducing the time required to take an aisle measurement while providing the user with amazingly fast data acquisition, naturally speeding up turn around times thus ensuring necessary changes are made to flooring relatively quickly.

The Somero SXPD is one magnificent piece of machinery, although its electronics are still not immune to the tests of time. Automatic republic did a full replacement of the damaged HMI. In addition to a new modern Bgk C20 PLC with Can-Bus.

Our team of experienced technicians managed to pull function controls from the old system and rewrote the code to the newer PLC, bringing this astounding hardware back to life.

Now our client can once again be able to perfectly level out their clients concrete flooring with precision.

Hydraulic Pumps

To create the perfect angles and manoeuvres

Thanks to the PLC, the position of the head can be controlled through the HMI, with the assistance of the laser guides, the head can be positioned precisely for the desired levelling/slope

Laser Guidance

For precise levelling of concrete flooring

Using the LAN (Can-Bus), the PLC is able to communicate and determine the appropriate position of the screed's head, using data read from the lasers on either side of the head.

Upper Frame Rotation

Allows 360 degrees of movement

The HMI accurately presents machine data, such as fuel levels, rotational degrees and scrapper head position. Allowing the user to position the head in the desired area

Automation Republic executed a comprehensive upgrade on a Concrete grinder machine. The project demanded seamlessly integrating rotational diamond discs, hydraulic extenders, movement controls onto the B&R control platform which is running on a

We pride ourselves on our control panels neat structure, ensuring organisation. The PLC is hardwired in conjunction with the necessary components of the machine. Connecting all controls to the HMI through ethernet.

The interchangeable synthetic diamond blades, are used for aggressive coating removal on concrete surfaces, with larger diamonds. Smaller diamond blades are used for polishing and honing applications. The disc rotation speed ranges from 250 rpm to over 3,000 rpm, all controlled from the HMI. Hydraulic lifts are used in adjacent with the PLC/HMI to control the height of the discs, to ensure appropriate depth of grinding is met.