Pharmaceutical projects

Our Project team has acquired a vast amount of experience working with multiple machines in the liquid industry.

Form, Fill and Seal

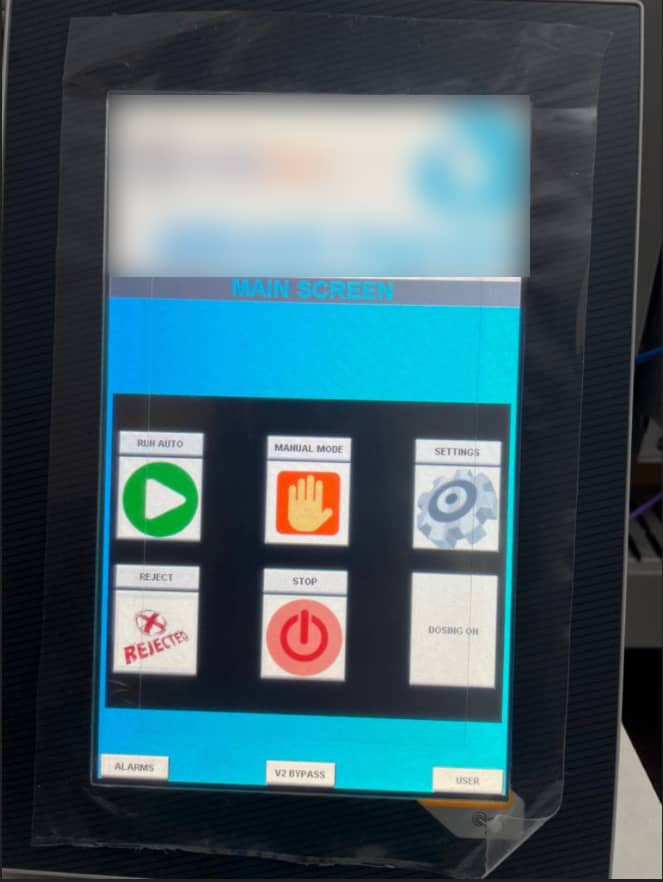

Form, fill and seal HMI-PLC Upgrade

Form, fill and seal machine had obsolete equipment and were becoming problematic for the customer. We were tasked to provide a solution for the customer. We determined which hardware needed to be replaced and what could still be used. We provided the customer with an upgrade solution that required using both existing and new hardware.

The machine needed to be re-programmed and the new hardware installed. We successfully upgraded the machine and received a comment from the customer stating that the machine worked even better than it originally did. They were very impressed with the outcome.

Automation Republic was able to provide an updated HMI. Our qualified team of professional programmers created a comprehensive alarm and monitoring system. The system allowed for the PLC to read, monitor and send alerts on any of the machines components, to prevent misuse and product defects.

Filling and Capping System

Filing and capping of pre-capped microtubes

The Pharmaceutical industry is a massive economic field, with a constant demand for consumables.

Most diagnostic companies achieve very significant benefits from the consistency of process in filling and capping increasing production yields, optimised sales revenue and reduced error costs

Automation republic assisted in revamping a Dencore MTF50’s PLC and HMI. The project required precise accuracy from the fill nozzle, adjustable speed of the feeding belt , syncing of uncapping and recapping component and liquid pumps all through the PLC.

We also provided the client with rewiring of the control panel and a new HMI with full control over the operation of the machine.

Our team managed two create the software to allow the machine to function under stated performance. Depending on the filling layout, the unit handles fill volumes from 5µl to 2ml at speeds up to 600 units per hour.